The manufacture of bags for packing Suger typically involves the following steps:

1. Material Selection: The bags are manufactured from high-quality food-grade materials that are approved for packaging food items like sugar. Common materials include Polyester (PE) or Low-density polyethylene (LDPE).

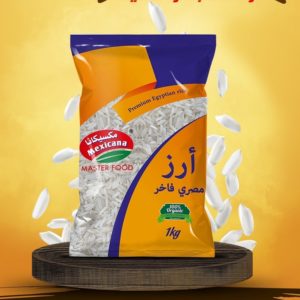

2. Printing: If required, the bags can be printed with relevant information like the brand name, logo, product details, or nutrition facts. This is done using flexographic printing techniques.

3. Lamination: Sometimes, bags are laminated with a thin film layer to further protect the sugar from moisture, air, or external contaminants. This layer can be made from materials like polyethylene (PE), providing additional barrier properties.

4. Bag Making: The plastic sheets are cut into the desired bag size and shape using specialized machines. This process includes folding, perforating, heat-sealing, and adding handles or closures like zippers or adhesives if necessary.

5. Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the bags meet the required standards and regulations. This includes checks for weight consistency, seal strength, print quality, and overall integrity.

6. Packaging: Once the bags are manufactured and quality checked, they are packed in bundles for transportation and distribution to packaging companies.

It’s important to note that sugar bags must meet specific regulatory requirements, such as being food-safe, chemically inert, and able to withstand transportation and storage conditions.

Reviews

There are no reviews yet.